Liquid phase purification by means of adsorption

Biorefineries play a central role in the quest for a sustainable bio-based future. One challenge is the selection of the separation technique due to the large water volumes processed, the product inhibition, the low concentrated feeds and product yields [1]. A promising solution is the use of adsorption as it offers a lower energy consumption compared to distillation and has a lower capex investment due to its relatively simple installation [1].

We in Avantium take the transition to a sustainable world seriously and therefore wanted to apply our experience from accelerating catalyst testing to accelerate adsorption development [2]. Conventional adsorption testing takes a long time and uses large amounts of testing material while with enhanced experimentation tests this will only take a fraction of time and use of chemicals compared to the conventional approach [3]. This year we developed a high-throughput liquid adsorption system which can execute separations as well as purifications. Our first results are shown in this article.

Test description

The challenge was to replace a distillation solution which was limited by azeotropes, with an adsorption solution. A three stage program was set up consisting of exploring the existing window of conditions, screen experiments to identify the appropriate adsorbents and finally an optimizing stage to determine the optimal adsorption and desorption conditions. Within 3 month and a total of twenty experiments Avantium was able to define the appropriate conditions and most promising adsorbents achieve target product purity.

Our first results

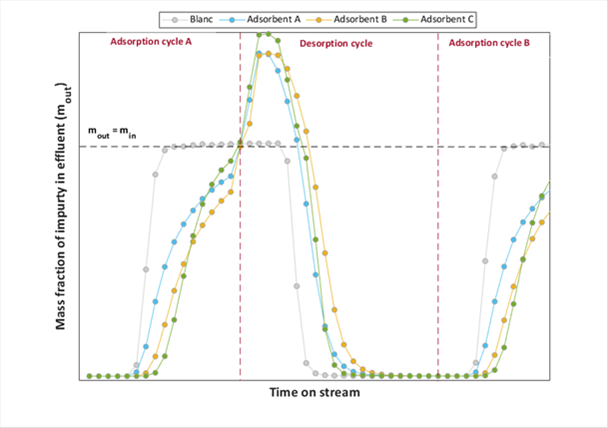

A review of available information in the public domain pointed to activated carbon as the most promising class of adsorbents, and therefore these were the focus of the testing work. A typical result of an adsorption test is shown below on the left where the vertical axis shows the measured impurity levels, the horizontal axis shows the time.In the test three sets of adsorbents were subsequently subjected to adsorption/desorption cycle where a reactor packed with inert material is used to establish the performance baseline. An offline chromatography analysis was used to analyze the samples.

The raw data as seen on the left side is mathematically reworked to get the adsorbent capacities, the rates of adsorption/desorption and other key performance indicators to directly translate these tests into a scaled process design that predicts what adsorption material has the longest life time, the expected throughput per column, its volume and how much columns are needed.

As you can see on the right side adsorbent C can purify significantly more feed compared to adsorbent A. The advantage of this test approach compared to a conventional test was not only saving time and materials but moreover the experimental errors were reduced as all adsorbents saw the exact same conditions.

In short, at Avantium we have developed an effective, fast and accurate small-scale high-throughput testing capability for all types of liquid adsorption process and adsorbents which will accelerate the development of new adsorbents and separation solutions.

[1] Separation technology-Making a difference in iorefineries, Kiss, A.A., Lange, J-P., Schuur, B. Brilman, D.W.F., Ham vd., A.G.J., Kersten, S.R.A., Biomass and Bioenergy, 95, 2016, 296-309.

[2] A Review of Biorefinery Separations for Bioproduct Production via Thermocatalytic Processing, Nguyen, H., Annual Review of Chemical and Biomolecular Engineering , 8, 2017, 115-137

[3] Predicting GAC Performance with Rapid Small-Scale Test Columns, Crittenden., J.C. et. al. JournalAWWA, Reseach & Technology, 83-1, 1991, 77-87